Key Technology purchases the base material from blast furnace steel manufacturers and offers a totally integrated production system, from cutting, secondary processing, welding and painting to meet customer requirements.

Building a lower frame assembly

Key Technology boasts 7 gas cutting machines and 12 laser cutting machines accommodating sheet metal thickness from 3.2mm up to 120mm.

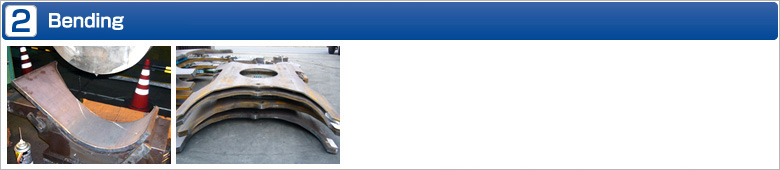

A range of small and large presses and a long 11m press make it possible to perform a range of bending operations.

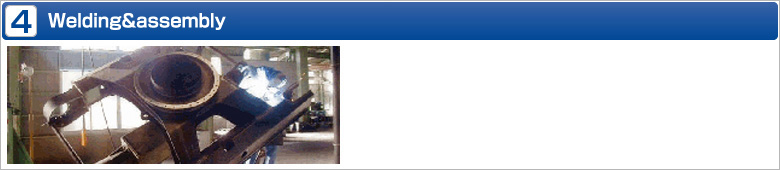

Welding processes using specialty jigs.

Assembly of the lower frame for a hydraulic excavator using a welding robot and 6 positioners.

High precision machining using 10 machines, including 5-face machining centers and horizontal boring and milling machines.

Painting to meet customer requirements.